The founder of Ginza Motoji, Koumei Motoji will hereinafter be referred to as Koumei. His son, and the current owner of the store Keita Motoji will be referred to as Keita.

Keita: Last year was an eventful year for everyone involved in Basho-fu as, the godmother of Basho-fu and designated living national treasure Taira Toshiko passed away at 101 years of age. Taira is accredited for the rejuvenation of making of Basho-fu after the devastation of World War II.

Taira Toshiko at her workshop spinning thread.

Koumei: In June of 2022, a comprehensive exhibition showcasing the work of Toshiko Taira took place, and a large number of Bashofu textile fans from all over Japan (many wearing basho-fu) gathered at the Okura Museum to see various works of Basho-fu, old and new. I can only assume that she departed for heaven with a smile, having witnessed the success of the exhibition.

Keita: I have only had the opportunity to meet her once in Kijoka, her hometown a few years ago. Even well into her 90s, seeing her serenely spinning thread in her workshop remains with me.

Taira Toshiko spinning thread with the founder of Ginza Motoji, Motoji Koumei.

Koumei: I was fortunate enough to visit her workshop many times, where she always was busy with spinning or dyeing. A few years ago, we also hosted her in store for a gallery talk. Despite speaking very little, her passion was apparent to those who visited. She is a woman who demonstrates her convictions through actions as opposed to words.

Keita: Basho-fu is made with threads taken from the basho tree. It is a plant which is part of the banana family.

The fields where Basho are grown were burnt to the ground during the second world war, and Taira Toshiko played a crucial role in reviving the Basho textile industry from the ground up.

Through her dedicated efforts, the once-blackened fields transformed into lush green landscapes, and she painstakingly produced thousands of meters of threads required for each kimono. Her actions played a vital role in the recovery of Basho-fu as a thriving textile industry.

In 1974, Kijoka's Bashofu was designated as an Important Intangible Cultural Property, recognizing its significance as a kimono production area. Yanagi Soetsu, a prominent figure in the Mingei folk craft movement, also praised the beauty of Bashofu.

The fact we can see, and let alone wear basho-fu today is directly due to Tairas heroic work over the past century, and her dedicated team and apprentices.

A field of Basho trees just behind the workshop.

Koumei: As opposed to prioritizing herself as an artist, Taira focused on cementing an entire production system to support the craft. She emphasized the establishment of a solid framework and system for producing high-quality textiles. These days her daughter-in-law, Taira Mieko, has taken over the workshop and is working tirelessly to carry on the legacy. The production of Basho-fu involves numerous tasks, almost all of which take place on the island. There is little outsourcing making it an extremely demanding endeavor.

Keita: Exactly! Most kimono makers throughout Japan begin with purchased threads to weave their fabric, or purchased fabric in which to dye their pattern.

In Kijoka, the production of Basho-fu begins just outside the workshop, where hundreds of Basho trees must be raised, felled, and stripped for thread. The short threads are then knotted together by hand to create long enough threads suitable for weaving and dyeing. After this lengthy process, the threads are finally dyed and woven.

In this picture you can see what a Basho tree looks like at about three years old. This is usually the prime size to fell the tree to make thread.

Koumei: Taira Mieko often says that " finally weaving the fabric is the ultimate reward." Considering that approximately 200 strands of Bashofu thread are required for a single kimono, it becomes evident how painstakingly long the whole process is.

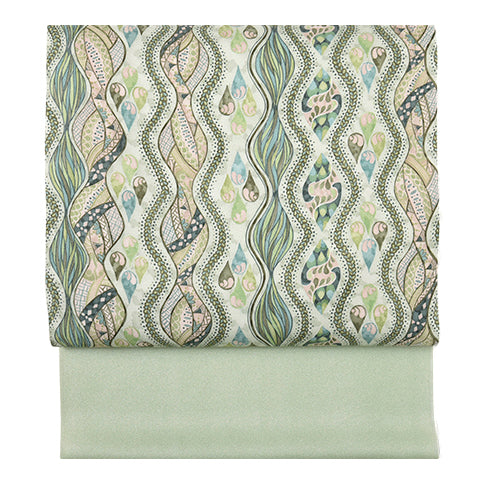

A Basho-fu kimono is coordinated featuring a Bingata obi.

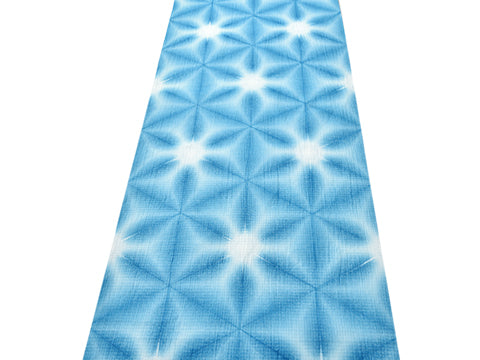

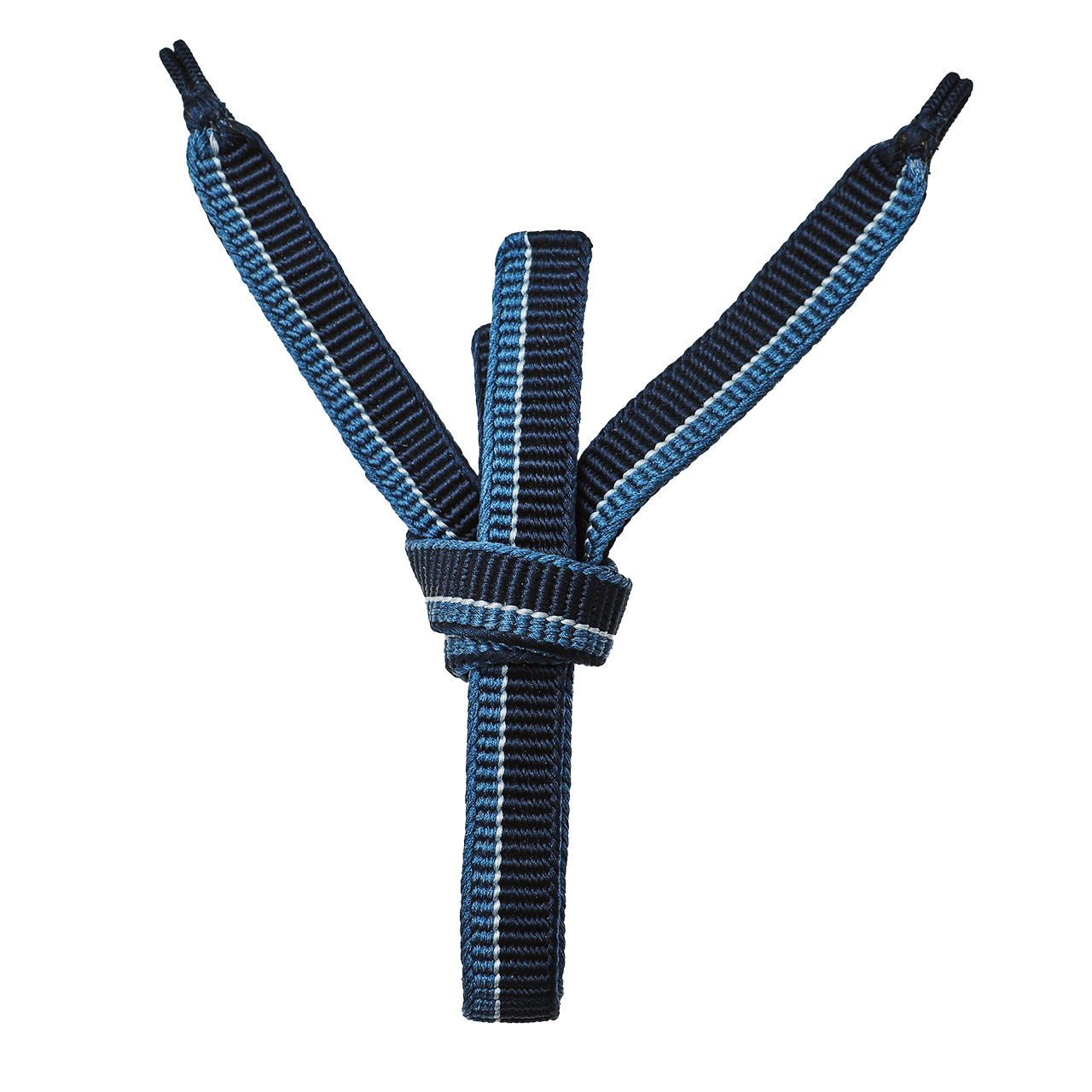

Keita: This time, we are showcasing a total of eight items, including nagoya obi, kimono, and mens kaku-obi. The kaku-obi featured in the exhibition is from the workshop of "Kikusan" on Yoron Island.

Yoron Islands: Kaku-Obi 「Two Stripes」

Koumei: Indeed, one of the captivating aspects of Yoron Island's Bashofu is the ability to appreciate the allure of the threads themselves. Even for men, simply choosing a kaku obi made of natural fabric like Basho-fu can elevate their look, especially during the summer season.

Koumei Motoji’s Top Pick「Nidashi Hana-ori Kakou」

Kyu-sun Nagoya Obiby Kijoka Basho-fu

I have chosen this striking red niigashii obi. Unlike other textiles, basho is extremely difficult to dye. To produce such rich colors, the threads must be boiled within the dyestuffs for extended time. Only top quality threads can withstand being dyed like this, therefore these obi are few and far between. Such fantastically colored items were traditionally reserved for royalty and the upper classes, though these days luckily can be worn by everyone. Why not choose a brilliantly vermillion obi this summer.

Keita Motoji’s Top Pick「Tatewaku Juji-kasuri」

Basho-fu Kimono「Swallows and Stripes」

Due to their extreme scarcity, this time we have only managed to get our hands on one kimono. To make a Basho-fu kimono, the threads must be impossibly thin, therefore just gathering the thread is a huge feat. This kimono showcases the natural color of the Basho, therefore would look fantastic on both men and women.

Basho-fu is quite sheer, but has body making it extremely comfortable to wear, and lets a breeze though, cooling the wearing magnificently.

名古屋帯

名古屋帯

袋帯

袋帯

紬・綿・自然布

紬・綿・自然布

小紋・江戸小紋

小紋・江戸小紋

訪問着・付下げ・色無地ほか

訪問着・付下げ・色無地ほか

浴衣・半巾帯

浴衣・半巾帯

羽織・コート

羽織・コート

肌着

肌着

小物

小物

履物

履物

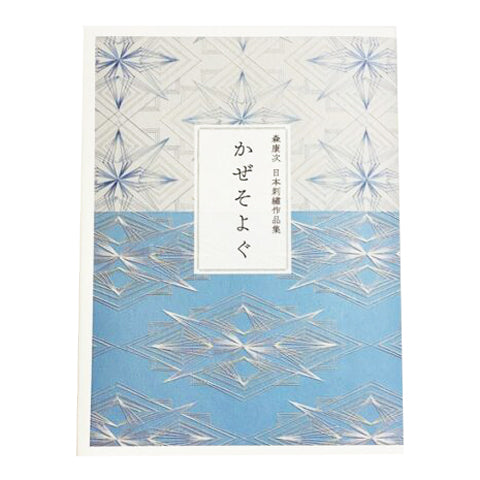

書籍

書籍

長襦袢

長襦袢

小物

小物

帯

帯

お召

お召

小紋・江戸小紋

小紋・江戸小紋

紬・綿・自然布

紬・綿・自然布

袴

袴

長襦袢

長襦袢

浴衣

浴衣

羽織・コート

羽織・コート

額裏

額裏

肌着

肌着

履物

履物

紋付

紋付

書籍

書籍