PHOTO: SHIGERU MASUI(AOI Pro. GROBAL)

What is Nagaita-Chugata?

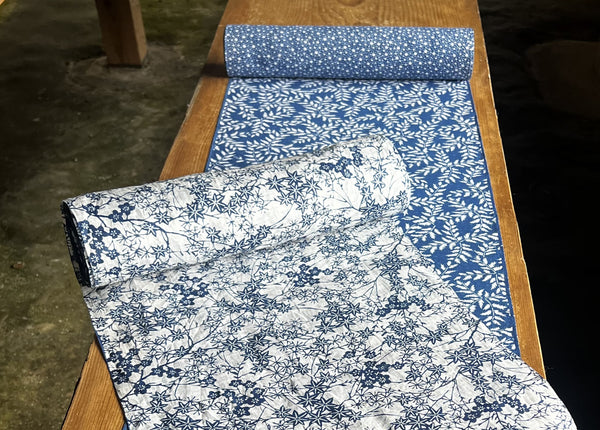

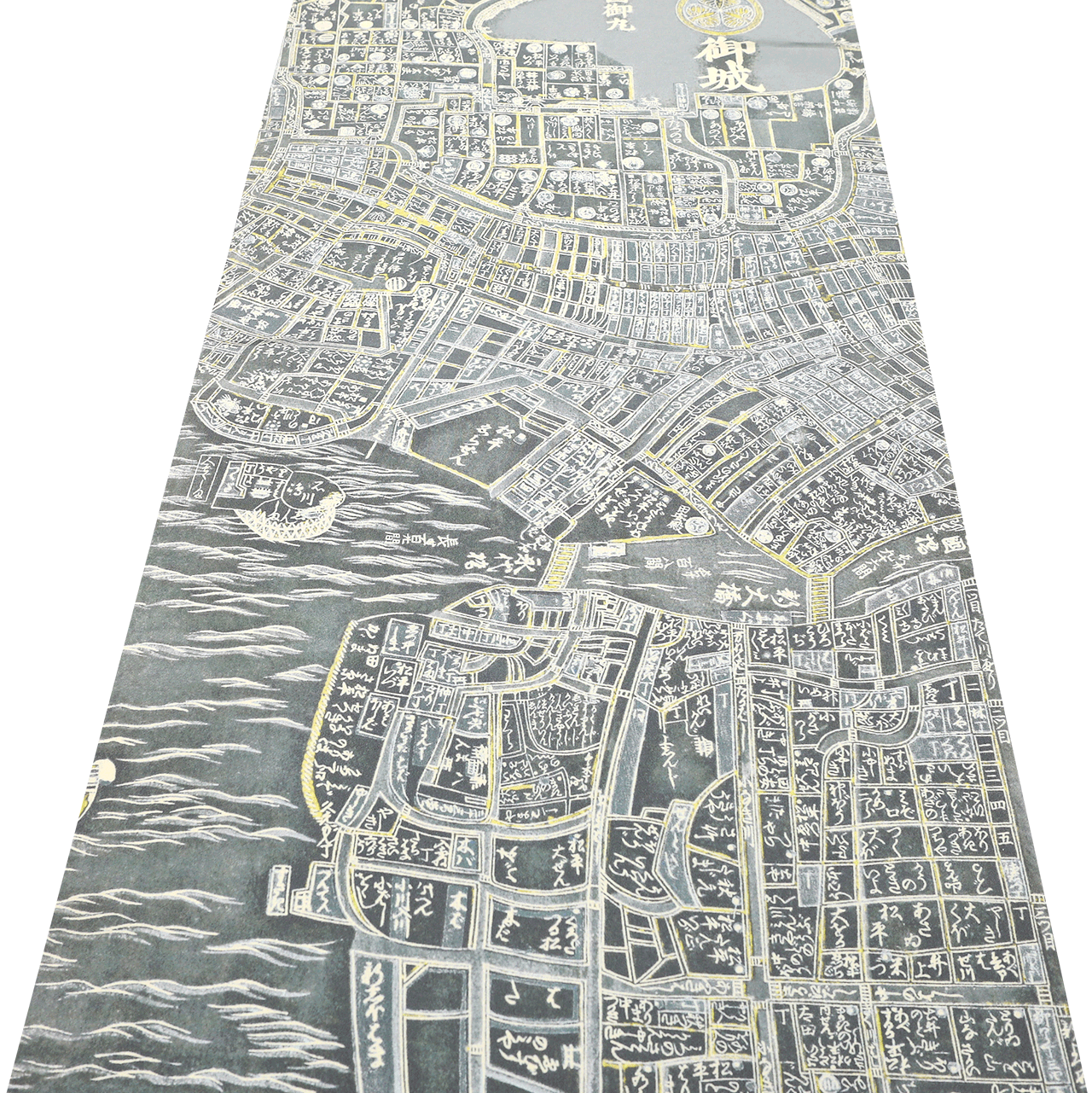

Nagaita-Chugata(長板中形) is a surface dyeing technique, where a hand-cut stencil is used to apply resist paste to the fabric, and then dyeing it in Indigo. This technique emerged in the Edo period. It was produced largely in Tokyo, earning it its nickname "Edo-Chugata".

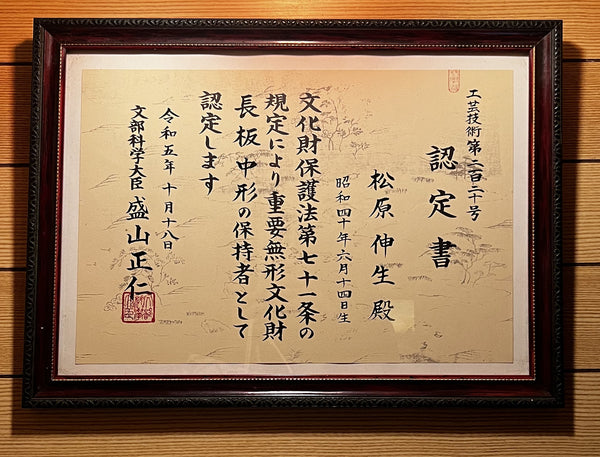

The name itself comes from the Nagaita(長板), the 6.5 meter long board used in its production, and the Chugata(中形), or the medium size stencils used to place the resists paste.The technique of Nagaita-Chugata was recognised as one of Japan's Important Intangible Cultural Properties in 1955, with Matsubara Sadakichi and Shimizu Kotaro being awarded status as Living National Treasures.

Requisite to be designated as Nagaita-Chugata

(1)The use of Ise-Katagami (Handcut paper stencils)

(2)Applying nori (resist paste) on both sides of the cloth.

(3)Using Indigo

About the Matsubara Family

MATSUBARA, Sadakichi(1893~1955)松原定吉氏

*Grandfather of Matsubara Nobuo

Born in Uozu City, Toyama Prefecture, Sadakichi moved to Tokyo at the age of 11 and began apprenticing. In 1955, he was designated as a Living National Treasure in the field of Nagaita-Chugata. Traditionally, the production of Nagaita-Chugata yukata involved separate individuals for each step of the process. This included stencil makers cutting stencils, specialists applying resist paste to the fabric, and dyers dyeing the fabric in indigo. Sadakichi himself streamlined the process by taking on the tasks of applying the resist paste and dyeing the fabric himself.

MATSUBARA, Toshio(1929~2005)松原利男氏

*Father of Matsubara Nobuo

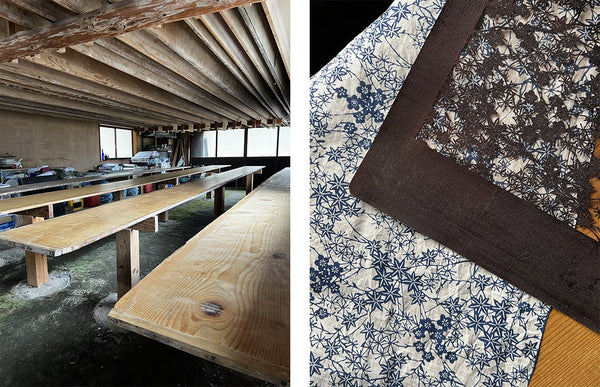

Matsubara Toshio was one of the four Matubara brothers, all of whom followed in their fathers footsteps in the world of Nagaita-Chugata. In 1984, When his son Nobuo was 19, he moved their dyeing studio to Kimitsu, Chiba, where he could make his work surrounded by nature.

He served as a director of the Japan Craft Association and as the chairperson of the Dyeing and Weaving Department.

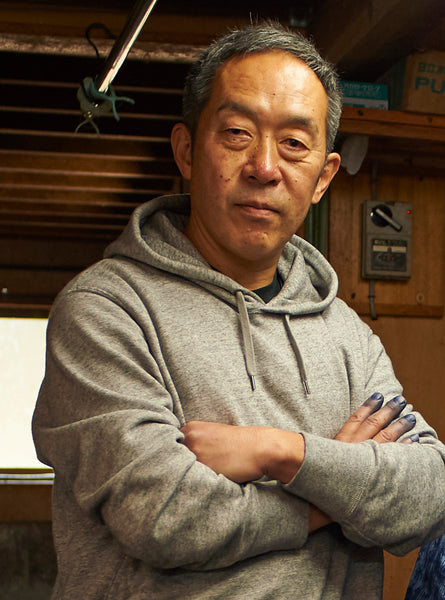

MATSUBARA, Nobuo (1965-) 松原伸生

Matsubara Nobuo was born in Edogawa City, Tokyo, in 1965.

After graduating from high school, Nobuo Matsubara studied under his father Toshio, who is also a regular member of the Japan Crafts Association, and has won numerous awards at many dyeing and weaving exhibitions. His current studio is located in Kimitsu City, Chiba Prefecture, where he moved to when he was 19 years old. Here in his studio surrounded by nature, he dyes his masterpieces by hand, ensuring the future of his craft.

Nobuo, like his grandfather Sadakichi, was decorated as a Living National Treasure in the field of Nagaita-Chugata in 2023.

Becoming a Living National Treasure (人間国宝)

Chiba's first Living National Treasure in 20 years, and Kimitsu City's first ever.

After the passing of Living National Treasure Yukitaro Shimizu in 1988, 36 years have passed since the last designation in the field of Nagaita-Chugata. This time, the designation of Nagaita-Chugata has been called a 'resurrection designation' in the field of crafts. After the death of a designated person, the designation in that field is temporarily revoked, making this the longest vacancy in the Living National Treasures crafts category.

Although Matsubara has received numerous awards before, each award is a reward for his accumulated efforts. This designation aims to broaden recognition of Nagaita-Chugata, provide guidance and leadership for passing on the technique, and nurture the next generation. He expresses feeling the weight of this responsibility. Expectations for Matsubara, who became a Living National Treasure at the age of 58, are quite high.

Sadakichi Matsubara had four sons known as the "Matsubara Brothers": Fukuyo, Toshio (Matsubara Nobuos father), Hakkou, and Yoshichi. These four brothers all worked in the family studio producing Nagaita-Chugata.

Continuing the family business has had its challenges. When Nobuo was 19, his father Toshio decided to work independantly. Seeking sunlight, water, and wind, he moved to Kimitsu City in Chiba Prefecture. Nobuo says that this move enabled his father to continue working, and pass the texhnique down to him.

Nagaita-Chugata is a technique with roots in nature.

Among the dense forest, freshwater streams, bathed in sun, lies Matsubaras studio. Craftsmanship is intimately connected with nature. In the production process, clear days are crucial, and typically, the nori is left for one day on both sides. During the rainy season, outdoor work is impossible, so the work tends to increase from autumn to winter when the air is dry and the paste is less prone to damage. The earthen floor in the studio retains humidity. so much so that moss even grows. Matsubaras work can only progress in consultation with the day's weather and humidity.

The Ise-Katagami used in the production of Nagaita-Chugata are often of the "Tsukibori" variety. These stencils are handcut with a blade, therefore producing flowing natural designs.

Nagaita-Chugata is to express pattern,

Edo-Komon is to express colour.

Once the fabric is rolled out on the long boards, the nori (resist paste) is applied using the stencil. It is an extremely sensetive proccess. The nori, is made from a mix of rice flour, rice bran, and lime. The amount of each ingredient used, as well as the amount of water depends on the weather, and humidity.

Stencils with a lot of negative space are often reinfornced with thin threads or mesh. To ensure these threads dont appear in the final pattern, a slightly thicker nori is used, called nebai-nori. Patterns with a lot of negative space, result in more aread covered in nori, and consuqently less area is dyed with the indigo.

Stencils with finer patterns, a slightly lighter nori called sakui-nori is used.

*Sakui-nori is the nori often used in the creation of Edo-Komon

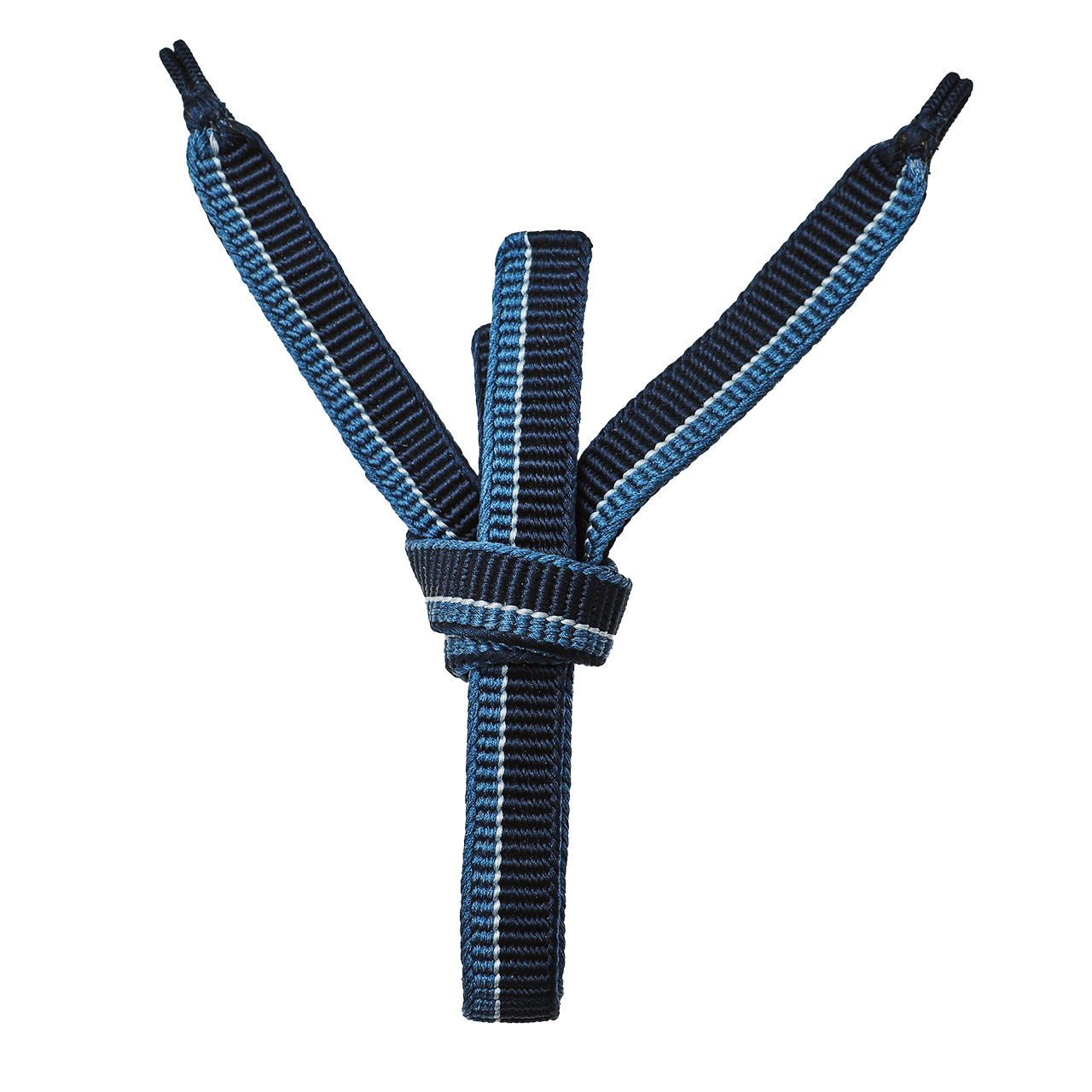

Using Shinshi (伸子)

Shinshi are bamboo rods with pins in either end, used to stretch the fabric. They all must be about the same size and bend the same amount, so they must all be chosen carefully. If they are not evenly tentioned they can pop off when in the dye vat.

The shinshi are chosen based on their on the weight of the fabric, as well as the weight of the nori.

Usually when Yuzen dyeing, Shinshi are applied to both sides of the fabric, and the dye is applied by hand. In the case of Nagaita-Chugata, the fabric is only stretched on one side with shinshi, folded up, and then dyed in a vat. One bolt of cloth (12 to 13 meters) is stretched using about 32 shinshi.

Dying the Matsubara way.

The vat used to dye the fabric is unique to the Matsubara family. Regular dye vats are round, but the Matsubaras is rectangular. This is because the fabric is folded neatly into a large accordion for easy handing, drying, and dyeing. The rectangular shape leaves no waste of space. This is an extremely imporant task, and must be done slowly, are precisely.

Inside the vat, there is a heater keeping the indigo warm. Its set to about 20 degrees.

To ensure the fabric doesnt stick together,, matsubara blows onto the fabric to keep the folds seperate.

From the moment the fabric is dropped into the dye, until it has been removed is the most nerveracking.

Just one mistake could render the whole process a mistake. the tention is palpable.

Once the fabric comes out of the dye. It is initially green.

It begins to ozidize, and quickly turns blue.

Depending on the amount of times the fabric is submerged, the colour deepens. Matsubara usually dips the fabric into to indigo around two or three times. Any more than four times and the nori begins to compromise.

To demonstrate one's skills, tools are essential. In a workshop, well-maintained tools are neatly arranged and kept tidy.

It seems that a new hinoki spatula works better after the corners have been rounded out before using them.

The brushes used for go-ire (a Japanese dyeing technique) are made with domestically sourced deer hair, which has seen changes in quality and a rise in prices. It seems that tools such as brushes, spatulas, and needles for stretching fabric have also evolved over the years.

Furthermore, comparing the past and present, there have been changes not only in tools but also in weather and climate conditions, as well as in materials. (For example, rice bran has become coarser than before, so he must put extra effort into straining it.) Additionally, customer preferences have changed, so it is necessary to adapt flexibly to these changes.

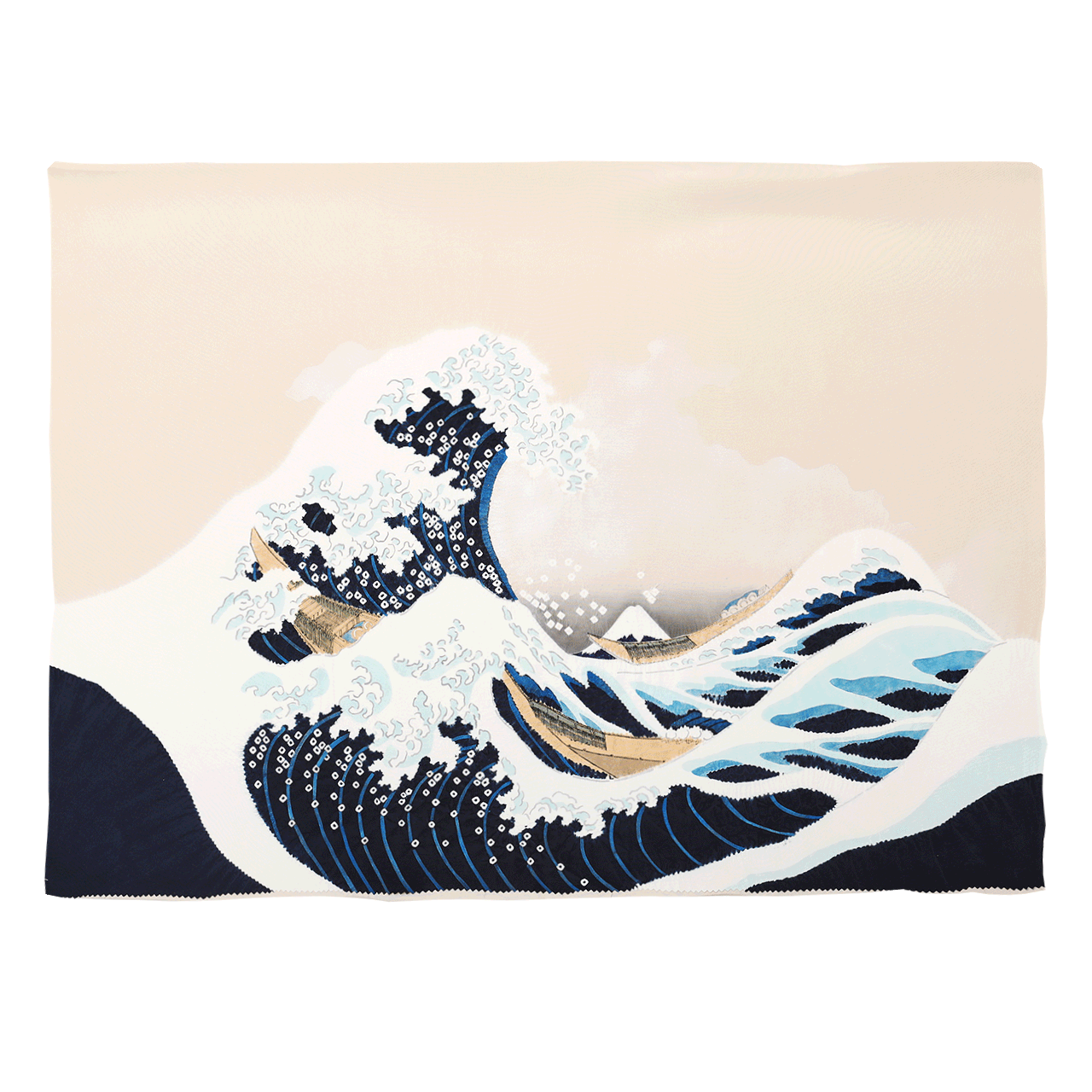

One of the most attractive parts of Nagaita-Chugata kimono is its double sided patterns, and the coolness born from the contrast between its indigo and white. With its roots in yukata, it is both cool to wear and refreshing to look at, possessing the power to cool down the sweltering Japanese summers.

Though traditionally worn just as yukata, nowadays people also pair their Matsubara masterpiece with a nagajuban, and dress it up with a nagoya-obi, wearing it as a casual kimono. Wearing it like this means one can wear it not just in the summer, but also in the hitoe season (June and September)

The making of Nagaita-Chugata

名古屋帯

名古屋帯

袋帯

袋帯

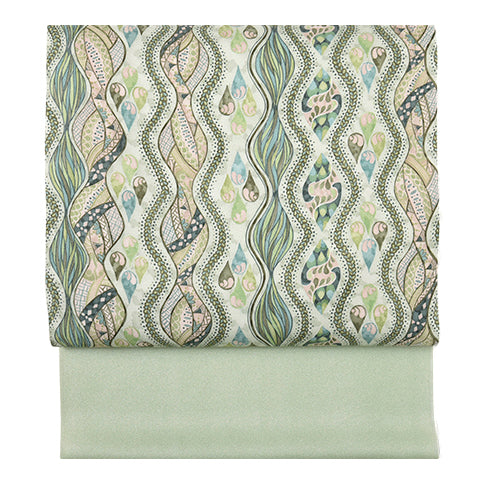

紬・綿・自然布

紬・綿・自然布

小紋・江戸小紋

小紋・江戸小紋

訪問着・付下げ・色無地ほか

訪問着・付下げ・色無地ほか

浴衣・半巾帯

浴衣・半巾帯

羽織・コート

羽織・コート

肌着

肌着

小物

小物

履物

履物

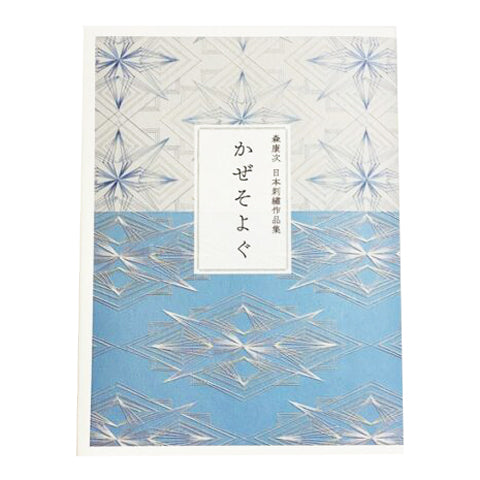

書籍

書籍

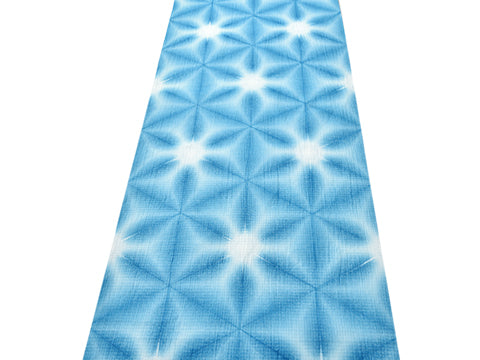

長襦袢

長襦袢

小物

小物

帯

帯

お召

お召

小紋・江戸小紋

小紋・江戸小紋

紬・綿・自然布

紬・綿・自然布

袴

袴

長襦袢

長襦袢

浴衣

浴衣

羽織・コート

羽織・コート

額裏

額裏

肌着

肌着

履物

履物

紋付

紋付

書籍

書籍